AGENDA OF THE MECHANICAL ENGINEERING COURSE

The training modules are periodically updated to adapt to the latest needs of the industrial market. In addition, we take our students' doubts very seriously, we solve ALL of them and we record new classes to solve them.

We already have students from more than 15 countries, 10 fully developed modules and more than 30 high engineering problems. Everything to sweep your professional environment!

MODULE 1: Cutting in manufacturing

You will learn the technologies for handling steels, aluminum and other metals. In addition, you will know the ways to implement it in your industry.

MODULE 2: Application of welding

You will learn the different types of welding, regulations and technical criteria to develop steel structures and complete machines.

MODULE 3: Turning and machining

You will learn to differentiate what type of processes your designs need and which is the one with the best value for money. In addition, we will explain in detail what parameters must be indicated in the plans to outsource manufacturing.

MODULE 4: Mechanical Design Elements

You will learn to choose mechanical components and to integrate them into your designs. In this way you will learn its implementation and save as much as possible in the design and manufacture of industrial machinery.

MODULE 5: Engineering value chain

In this training module we unravel the secrets of engineering and explain what the complete manufacturing process is so that you can locate the bottlenecks in your process.

MODULE 6: Stages and components of a project

In this module we divide an engineering project into several parts and explain the key points of each of them.

MODULE 7: Hydraulics and pneumatics

A quality mechanical design has other very important components that give designs movement. In this module we will focus on explaining in detail all the hydraulic and pneumatic parts.

MODULE 8: Electricity and control

To control all the moving components of the machinery a phase of electricity and control is necessary. In this field we speak not only of electric motors but also of sensors, drives and automatons.

MODULE 9: Lifting and translation equipment

This module is different. You will learn to design lifting and translation components.

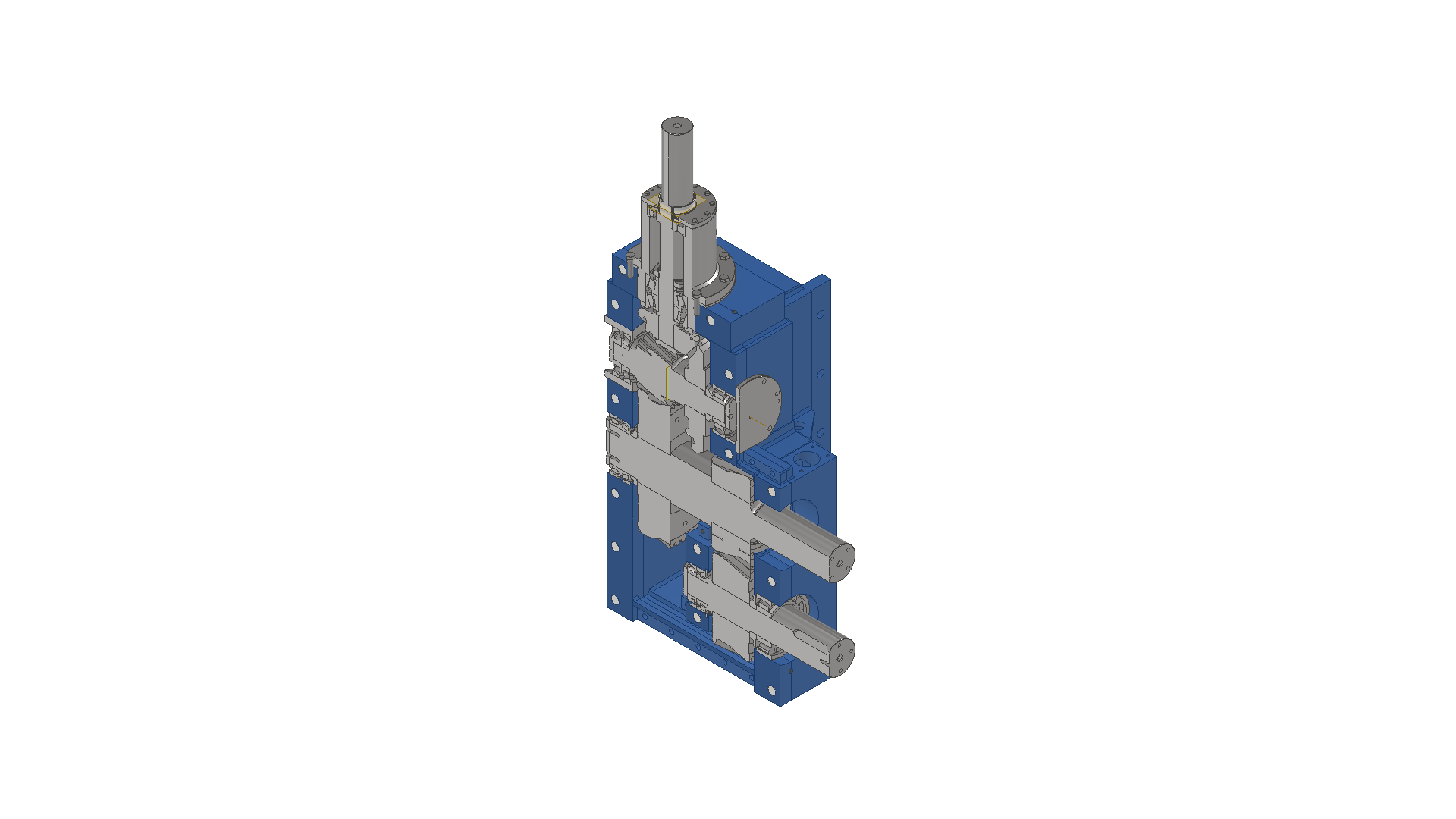

MODULE 10: Transmission of movements

In this module you will learn to transform movements, for example, change a vertical movement into a horizontal one or a horizontal one into two vertical ones… Everything is possible if you know how.